2013

J&C Company has every service your company will need to complete your project, from initial design to finished product. We can assist you through the engineering, prototype, and production stages of the project. Every service necessary for your project is right here at J&C Company. We are organized to economically engineer, design, and assemble high quality products on either a short term or a long term basis. Take advantage of our staff's thirty plus years of experience in assembly, design, engineering, and vendor relations. We will work together with you toward the successful completion of your project. J&C Company is equipped to handle your entire project, or any phase of it.

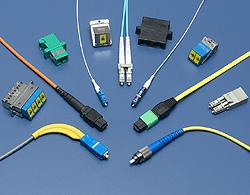

J&C Company is a well-established company providing contract assembly of cable assemblies/wire harnesses, printed circuit boards and electromechanical assemblies. Our customers rely on us for small to large production volumes, with both short run and weekly production capabilities. Experienced personnel in our production, purchasing, inventory management, and engineering departments insure your product will be built to your specifications, on time, with quality assured. We specialize in providing services to companies needing expertise in developing a concept or prototype into a production ready product. If your product needs engineering development work, from prototypes to circuit board layout, we can make it happen.

Quality Control.

Trained assemblers.

Learning curve costs are eliminated when you work with J&C Company. Our Production team is trained in the skills necessary to assemble your product. And, they have access to the equipment required to complete their tasks.Quality control procedures are implemented during all phases of the assembly process. Completed products receive 100% inspection prior to shipment by J&C Company. Product testing is performed to meet your requirements. Cami Research and custom made test fixtures and visual check used on every product that goes out the door.

Trained assemblers.

Learning curve costs are eliminated when you work with J&C Company. Our Production team is trained in the skills necessary to assemble your product. And, they have access to the equipment required to complete their tasks.Quality control procedures are implemented during all phases of the assembly process. Completed products receive 100% inspection prior to shipment by J&C Company. Product testing is performed to meet your requirements. Cami Research and custom made test fixtures and visual check used on every product that goes out the door.

Proper Equipment.

Large production runs are no problem for J&C Company. For printed circuit board assembly projects, we have lead bending/cutting equipment and a wave soldering machine. For cable and wire assembly operations, our in-house equipment includes several wire cutting/stripping machines and crimp terminal presses. We also have a milling machine to handle your enclosure or panel modification requirements.

Large production runs are no problem for J&C Company. For printed circuit board assembly projects, we have lead bending/cutting equipment and a wave soldering machine. For cable and wire assembly operations, our in-

Experienced Purchasing Department.

Our purchasing staff is familiar with all the components needed to complete your project, and they know where to get them. Our purchasing department will find the highest quality components, at the best prices and the shortest delivery times, to complete your project.

Speed and Accuracy.

We utilize Computer Aided Design (CAD) software to assist us in the timely completion of projects. The CAD software allows us to produce design drawings faster and more accurately. If you have changes, major or minor, the CAD software allows those changes to be made quickly. The CAD software can generate documentation for use in your company's support of your product.

Trained assemblers.

Learning curve costs are eliminated when you work with J&C Company. Our Production team is trained in the skills necessary to assemble your product. And, they have access to the equipment required to complete their tasks.

Learning curve costs are eliminated when you work with J&C Company. Our Production team is trained in the skills necessary to assemble your product. And, they have access to the equipment required to complete their tasks.